Lol that drawing does the rounds, the original is in my tool box

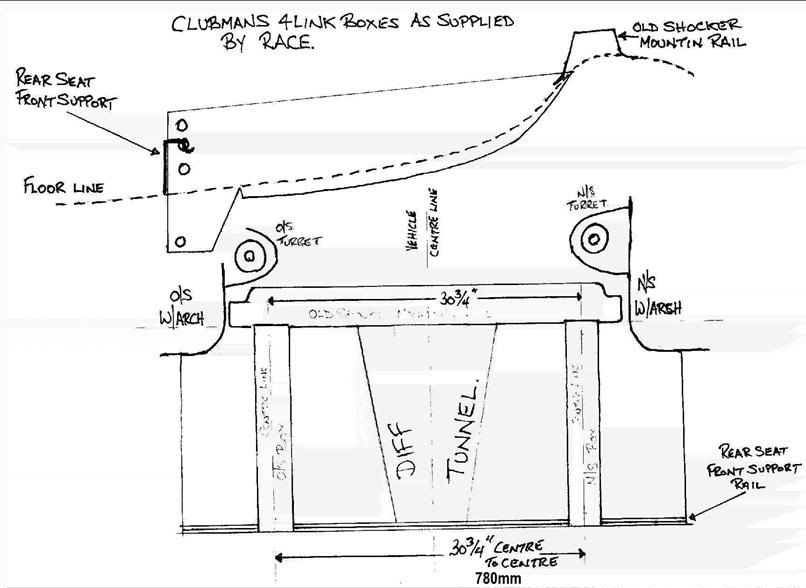

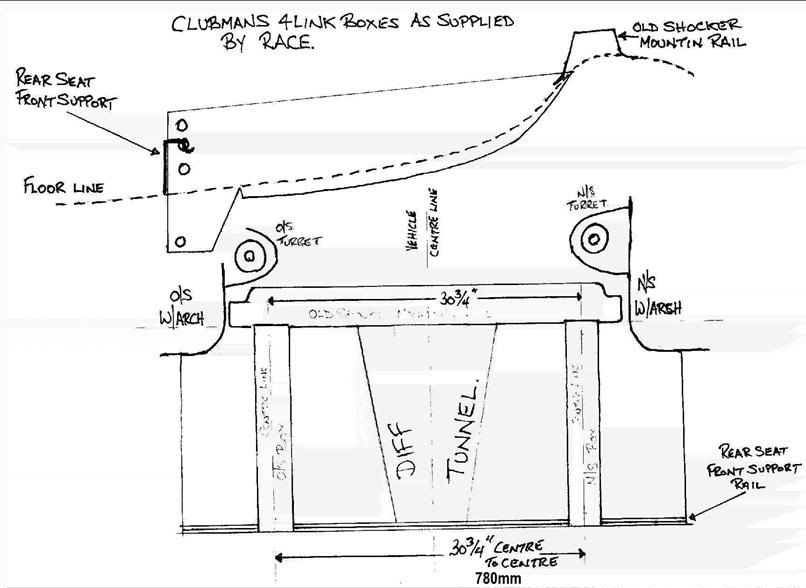

As said already, for one piece boxes use the top drawing, and front edge of the box fits against the rear seat crossmember, notch the return out to slide the box against the flat (vertical) face, weld the box to that part too, it makes a difference. This position is important or your link rods will be too long.

At the back the actual width is less important than making sure they are evenly spaced, you want to aim to cut the outer edge of the slot for the box so that it just nips into the lip on the chassis rail at it's rearmost point (hope that makes sense)

The width between the rails varies a fair amount on Escorts, so don't panic if it doesn't seem quite right.

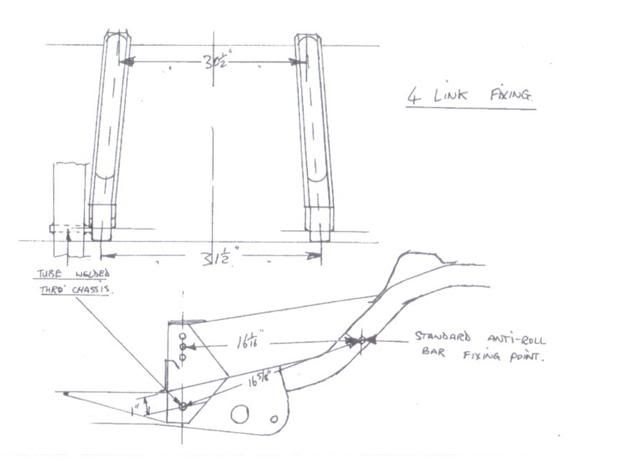

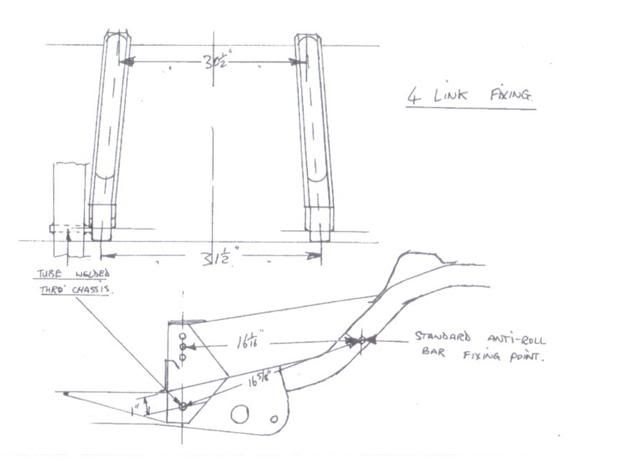

A neat way of doing this job with one piece boxes is to cut the slot about 16-20mm undersize (narrower) and then fold the surplus to make 2 90 degree flanges going upwards vertically, this will be much easier to get a good neat weld than trying to join 2 thin pieces of steel in a 90 degree butt weld, and again should result in a much stronger join

Any questions pm me if you want, I have fitted most types of these many times.

Hope that helps